Mixed Metals Case Study

Site Information

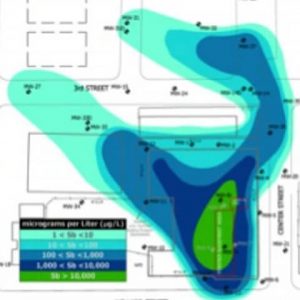

H&L Plating and Grinding, Inc. (2007-2015). This turn-key site remediation project included the development of a work plan to enter the site into the Indiana Voluntary Remediation Program (VRP), the scope of work included: site investigation (including lead and asbestos); waste characterization; waste management and disposal; equipment decontamination and relocation; decontamination of structures; structure demolition; shallow soil in situ remediation; deep soil in situ remediation; design and construction of an industrial wastewater treatment system; installation of a groundwater extraction and re-injection system; remote telemetry data acquisition; and long term monitoring for closure. The project was completed in 2015 for just less than $4.5 million dollars. Primary contaminants included hexavalent chromium, antimony, nickel, arsenic and lead. The remedy was implemented without deleterious changes to manganese and iron (secondary metals) present in groundwater at the site.

Nickel Pre-Treatment

1st Quarter Nickel

Hexchrome Pre-Treatment

5th Quarter Hexchrome

Antimony Pre-Treatment

4th Quarter Antimony

Additional Information

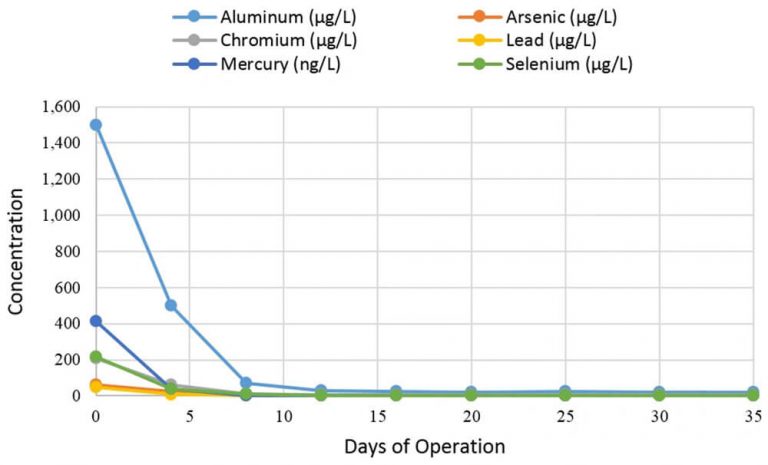

The table below shows the concentrations of six of the metal contaminants over time in the effluent from the column treated with the high dose of FerroBlack®-H.

The bench-scale treatability study consisted of testing the best-performing amendment from the batch studies (FerroBlack®-H) in column reactors to more closely simulate a PRB or a reactive zone in the field. Three PVC column reactors were set up to test a low and high dose of both FerroBlack®-H, plus a control column with no amendment. Each of the flow-through columns were carefully packed with homogenized soil from the site into which the appropriate amendment dose was mixed. Site groundwater was then passed through the columns at a specified flow rate and the effluent pore water from each column was analyzed for all the COCs at the site. In this way, each column simulated a PRB, and allowed the effectiveness of each amendment dose to remove COCs from site groundwater and prevent leaching of COCs from the site soil to be quantified.

TCE/SvOC Case Study

FerroBlack®-FS27 Treatability Study for TCE Groundwater Treatment

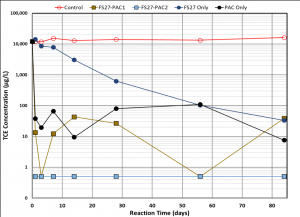

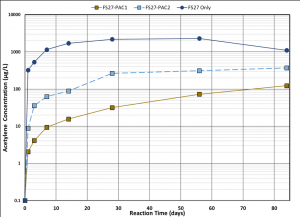

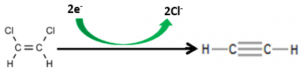

FerroBlack®-FS27 and two different PACs were tested alone or in combination. Although all of the reagents (alone or in combination) significantly lowered TCE concentrations over time, the production of acetylene (indicating TCE destruction through β-elimination) was only indicated when FerroBlack® (FS27) was present.

(Acetylene)

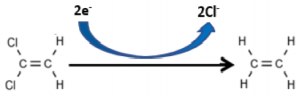

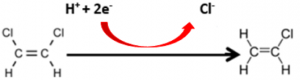

Hydrogenolysis – a chemical reaction whereby a single bond is cleaved between a carbon–carbon (or carbon–heteroatom) by reaction with hydrogen.

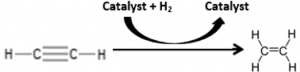

Hydrogenation– constitutes the addition of hydrogen (H2) to a multiple bond, usually in the presence of a catalyst such as nickel, palladium or platinum.

The process is commonly employed to reduce (or saturate) organic compounds.

References:

Jeong, H.Y.; Kim, H.Y.; Hayes, K.F. Reductive Dechlorination Pathways of Tetrachloroethylene and Trichloroethylene and Subsequent Transformation of Their Dechlorination Products by Mackinawite (FeS) in the Presence of Metals. Environ. Sci. Technol. 2007, 41, 7736-7743.

Hyun, S.P.; Hayes, K.F. Abiotic reductive dechlorination of cis-DCE by ferrous monosulfide mackinawite. Environ Sci Pollut Res (2015), 22, 16463–16474.